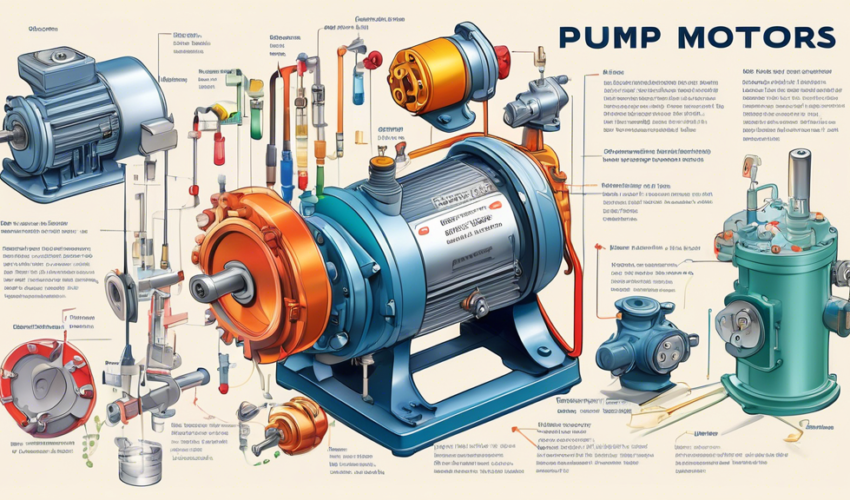

Pump motors are critical components in various industrial, residential, and commercial applications. They provide the necessary power to drive pumps, which in turn move fluids such as water, oils, and chemicals from one location to another. Understanding the different types of pump motors and their functions can help in selecting the right motor for specific applications, ensuring efficient and reliable operation.

Types of Pump Motors

There are several types of pump motors, each designed to meet specific requirements in terms of power, speed, and environmental conditions. The most common types include:

AC Induction Motors

AC induction motors are among the most widely used types of motors in pump applications. They operate on alternating current (AC) and are known for their durability and simplicity. AC induction motors can vary in size and horsepower, making them suitable for a wide range of applications, from small residential pumps to large industrial systems.

DC Motors

Direct current (DC) motors are another common type of pump motor, especially useful in applications requiring variable speed control. DC motors are typically used in portable devices or situations where battery power is utilized. Their capability to offer high starting torque and speed regulation makes them ideal for precise control in specialized pump operations.

Submersible Motors

Designed specifically for submersion in fluids, submersible motors are tightly sealed and waterproof. They are typically used in applications like deep well pumping, sewage treatment plants, and underwater operations. Submersible motors are highly efficient and protected against environmental factors.

Explosion Proof Motors

In industries where explosive gases or dust are present, such as oil and gas facilities, explosion proof motors are essential. These motors are designed to contain any internal explosion without igniting the external environment, ensuring the safety of the operation.

Synchronous Motors

Synchronous motors operate at a constant speed up to their full load. They are highly efficient and are often used in applications requiring precise speed control. These motors maintain consistent speed regardless of load variations, which is crucial for processes that rely on steady speed conditions.

Functions of Pump Motors

The principal function of a pump motor is to convert electrical energy into mechanical energy which drives a pump. Apart from this primary role, pump motors also perform various other functions:

Fluid Movement

By converting the motor’s rotational force into fluid movement, pump motors enable the transport of fluids across extensive systems. This is crucial in industries like water management, petrochemicals, and agriculture.

Pressure Regulation

In systems where pressure needs to be controlled or maintained, the motor’s speed can be regulated to adjust the pump’s output. This is critical in applications such as hydraulic systems and HVAC operations, where fluid pressure must be precisely controlled.

Energy Efficiency

Modern pump motors are designed to maximize energy efficiency, reducing operational costs and environmental impact. Efficient motors utilize advanced technologies such as variable frequency drives (VFDs) that adjust motor speed and torque to the load requirements.

Safety and Reliability

Safety is a key aspect of pump motor operation, especially in hazardous environments. Motors are equipped with features such as thermal protections, overload guards, and robust enclosures to ensure safe and reliable operation under varying conditions.

Choosing the Right Pump Motor

Choosing the right pump motor involves considering factors such as the type of fluid being pumped, required flow rate, head pressure, environmental conditions, and energy efficiency requirements. Understanding the specific needs of the application ensures that the selected motor not only meets the operational demands but also operates efficiently and cost-effectively.

In conclusion, pump motors are vital components in a wide range of applications, driving the operation and efficiency of pumping systems. Understanding the different types of motors and their functions helps in selecting the right motor, optimizing performance and ensuring durability.